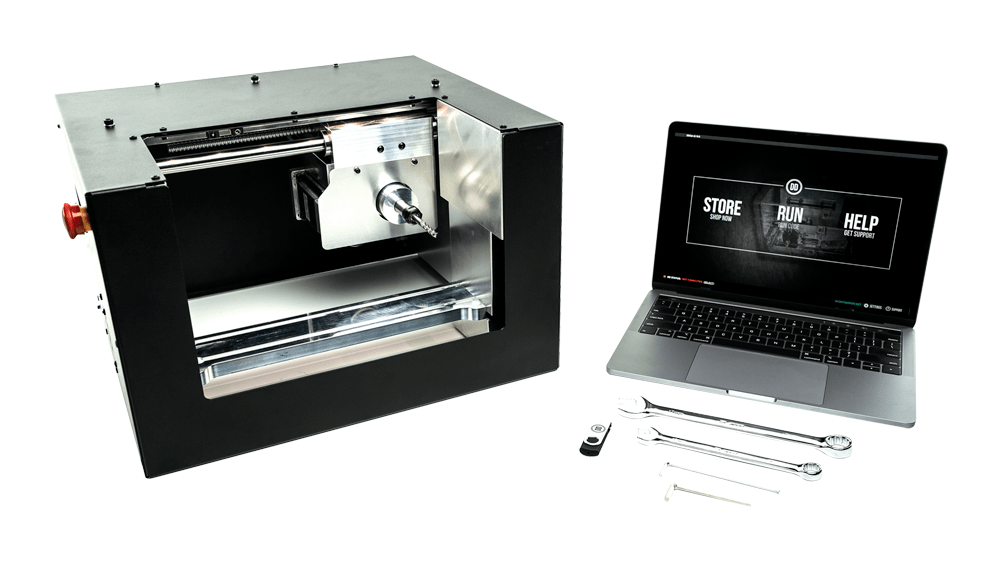

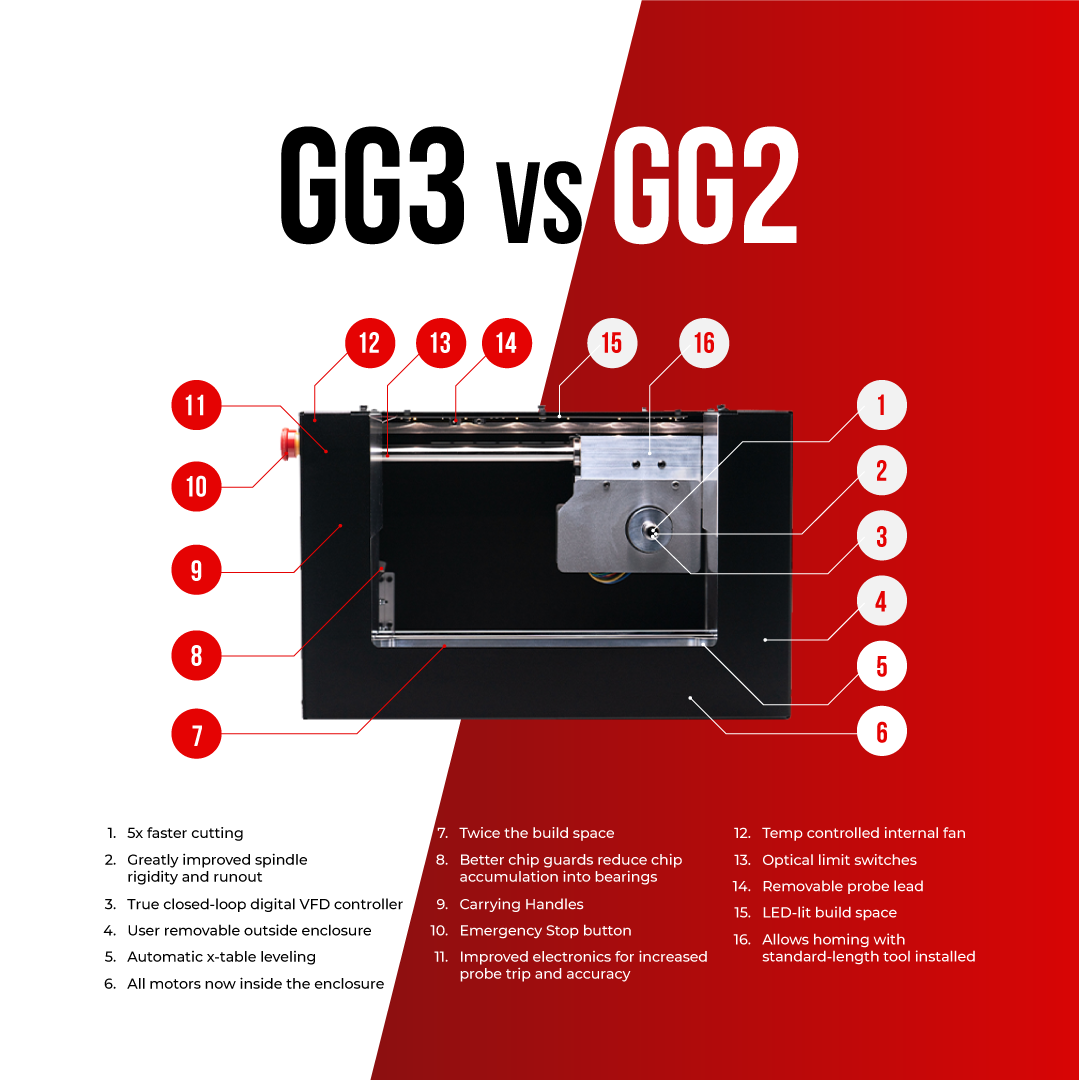

ghost gunner 3

Ghost Gunner is a general purpose CNC mill that gives you the ability to finish a growing library of mil-spec 80 percent lowers to completion.

5x faster

Automatic leveling

Illuminated

Full VFD

2x the build space

Cuts steel

ghost gunner 3-S

Ghost Gunner is a general purpose CNC mill that enables a growing library of gunsmithing applications. Engrave, customize, and finish 80 percent lowers to completion.

5x faster

Automatic leveling

Illuminated

Full VFD

2x the build space

Cuts steel

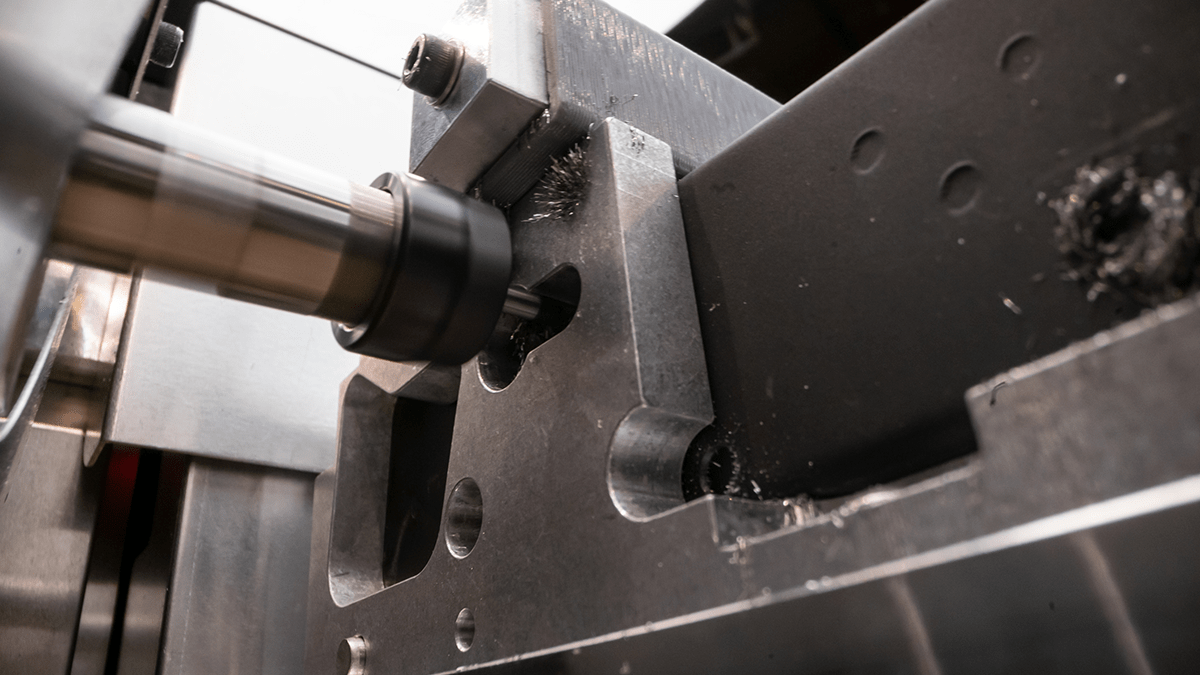

One Machine, Hundreds of Uses

The Ghost Gunner 3-S is fully open, fully programmable and can mill anything you want to make.

Cut shapes from flat metal. Engrave designs. Machine blocks into functional items. Mill circuit boards. And much more.

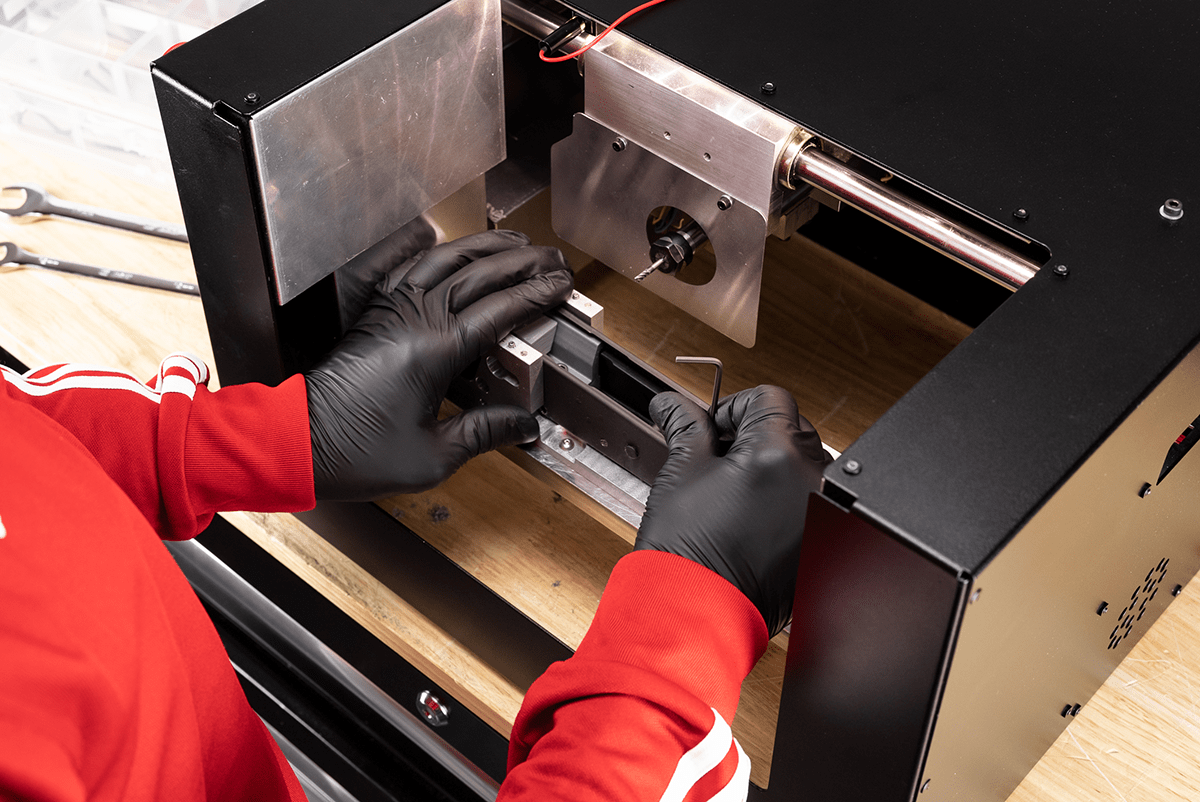

No Prior CNC Experience Required

With simple tools and point and click software, GG3-S is the perfect platform to learn and program a CNC, regardless of application.

No prior CNC skill is required to interact with community gunsmithing files. GG3-S is the most popular way of finishing unserialized rifles and pistols in the comfort and privacy of home.

No registration or serialization required

Due to Federal regulatory overreach, Ghost Gunner is now the only affordable CNC solution for privately finishing your 80% lower receivers. The first of its kind.

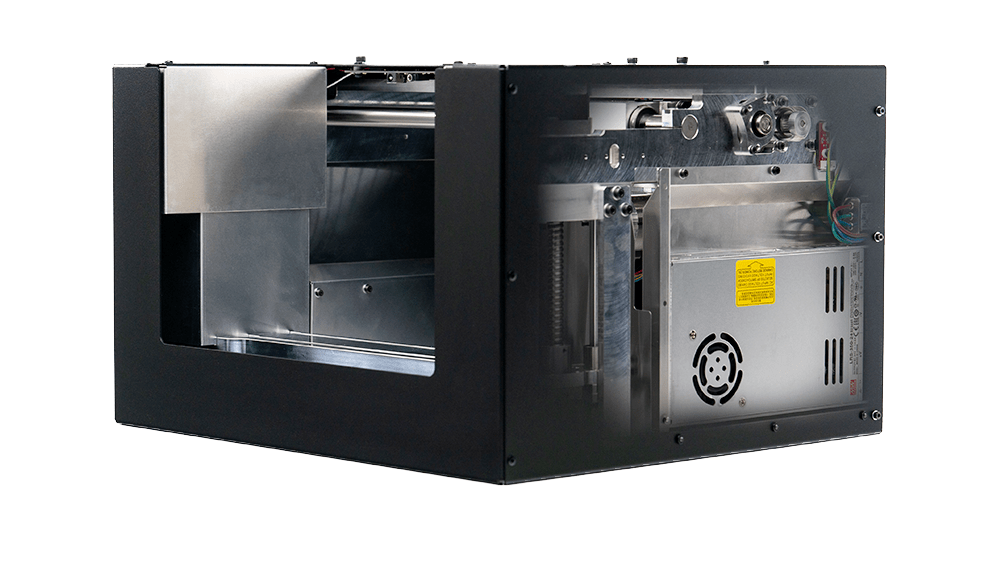

Programmable, Personal

Beyond files of our own .DD format, Ghost Gunner is meant to accept TinyG code from any CAM program. The platform is open and the plans and files will be disclosed to the public domain.

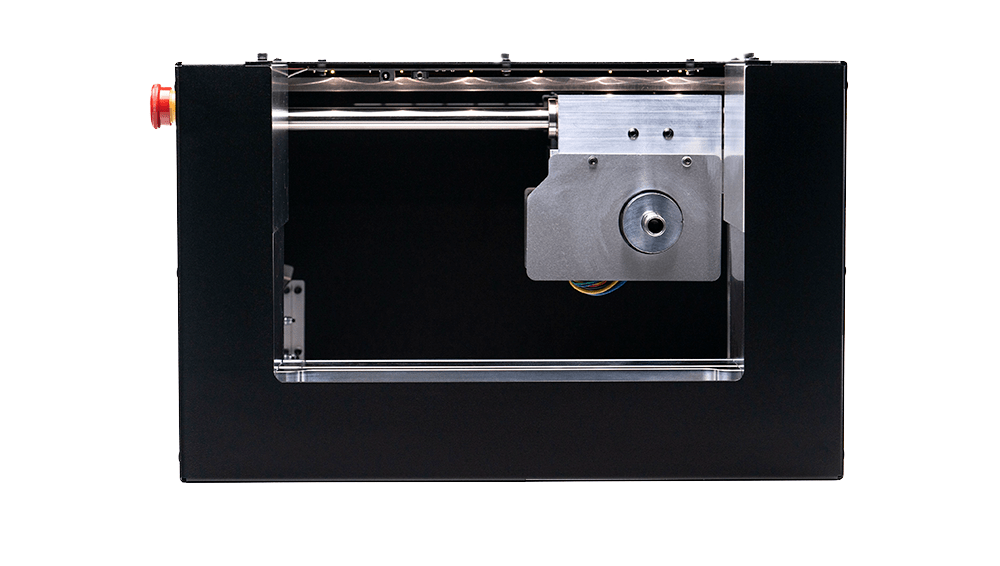

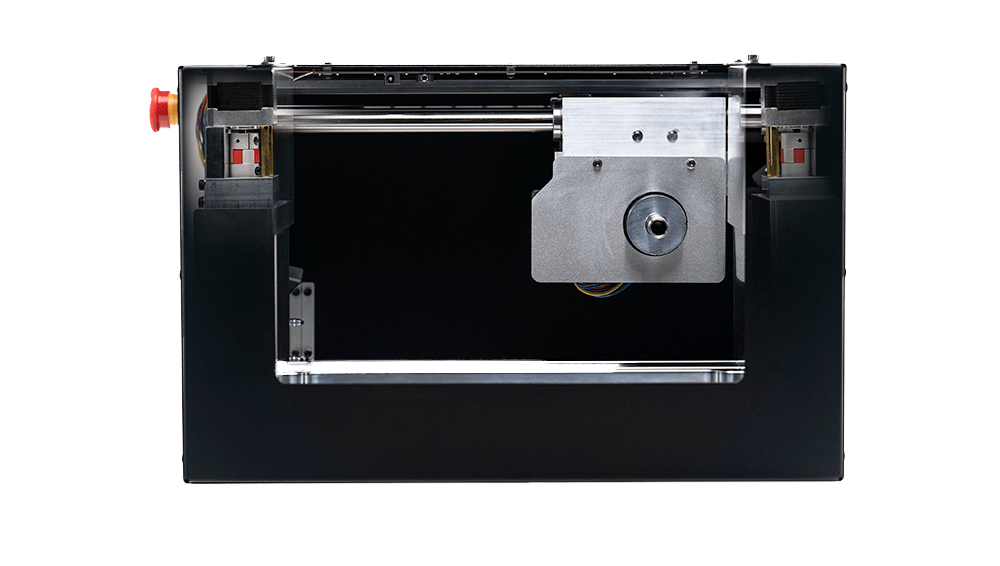

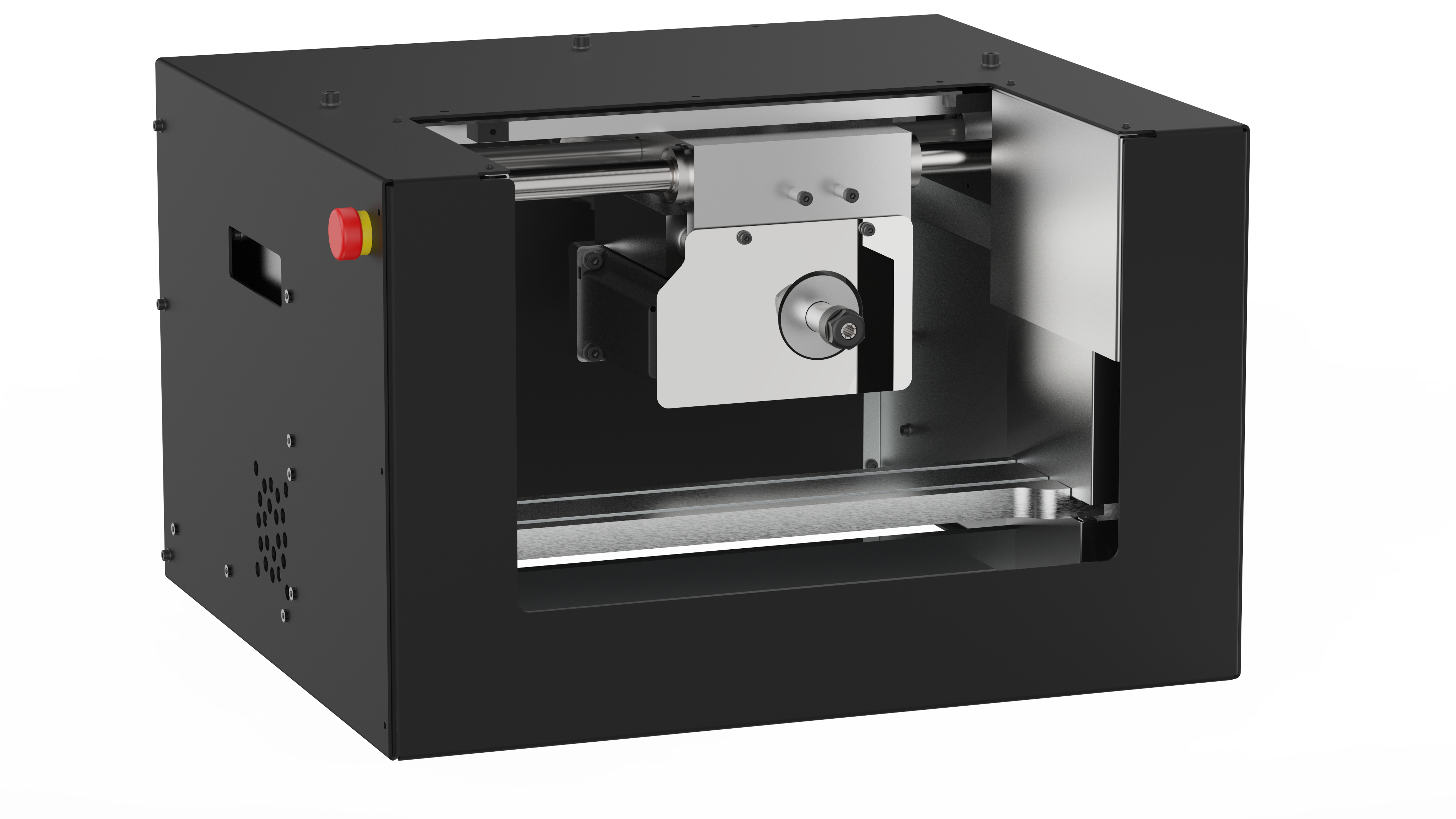

True CNC

Ghost Gunner is built from rigid aluminum unibodies, placed inside a plasma-cut A36 steel enclosure. The machine part count is greatly reduced compared to traditional CNC machines, which both increases rigidity and decreases cost.

GG3-S employs a horizontal milling format, a 9,000 rpm ER-11 collet unibody machined spindle and has a machinable area of 9.52" x 3.50" x 3.11", optimized for machining AR-15 and AK-47 receivers.